The Power of Preventative Maintenance: Reducing Costs & Extending Fleet Longevity

Preventative maintenance is the key to keeping your fleet running smoothly while minimizing downtime and unexpected costs. By addressing issues before they become costly repairs, you can save money, enhance vehicle longevity, and ensure operational efficiency. At Link-x.com, we understand the importance of a proactive approach to maintenance—whether you rely on an internal shop or third-party vendors. Here’s why preventative maintenance should be a top priority for your fleet management strategy.

Reduce Costs with Smart Maintenance Planning

One of the biggest advantages of preventative maintenance is cost reduction. Routine maintenance tasks—such as oil changes, tire rotations, and brake inspections—are far more affordable than major repairs or complete engine overhauls. By catching problems early, your team can make repairs in-house at a lower cost or work with your preferred vendors for competitive pricing.

A well-executed preventative maintenance program prevents costly emergency breakdowns, reducing downtime and ensuring your vehicles stay on the road, generating revenue instead of sitting in a repair shop.

Extend the Lifespan of Your Vehicles

Regular maintenance doesn’t just prevent breakdowns—it also extends the lifespan of your fleet. Vehicles that receive routine service experience less wear and tear, leading to a longer operational life. This means fewer vehicle replacements and a lower total cost of ownership.

By following manufacturer-recommended service intervals and proactively addressing small issues, you can maximize the return on investment (ROI) for each vehicle in your fleet. In the long run, this approach reduces capital expenditures on new vehicles while ensuring your existing assets remain reliable and efficient.

The Importance of Proper Tracking & Data Management

Whether you have an internal shop managing repairs or work with third-party vendors, tracking maintenance is crucial. Without an accurate record of what maintenance has been performed, you risk unnecessary repairs, compliance issues, and missed servicing schedules.

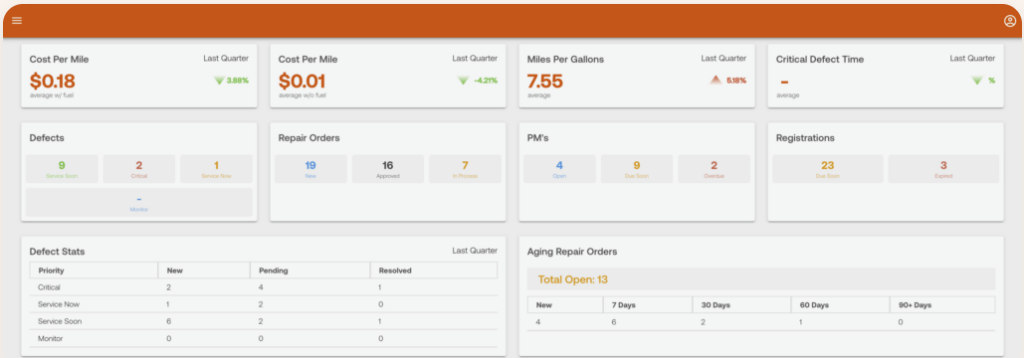

Using a fleet management system like Link-x.com allows you to track all maintenance activities in one place. You can:

- Schedule routine maintenance and receive automated reminders.

- Keep digital records of past repairs and service history.

- Monitor costs associated with maintenance, helping optimize budgets.

- Ensure compliance with safety and regulatory requirements.

Accurate tracking not only improves efficiency but also provides valuable insights into vehicle performance and maintenance trends, helping you make data-driven decisions to improve overall fleet management.

Partnering with the Right Vendors for Reliable Maintenance

Even if you don’t have an in-house shop, working with reliable third-party vendors ensures your vehicles receive the best possible service. By building relationships with preferred vendors, you can negotiate better pricing, ensure quality workmanship, and maintain consistency in service.

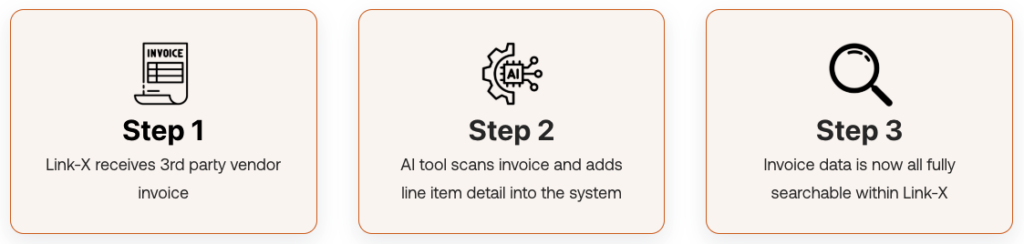

Should you elect to use third party vendors, Link-X automates the data collection and entry of invoices into the platform utilizing our cutting edge AI technology. We can take a digital or handwritten invoice and process it into the system. No data entry required on your end!

A preventative maintenance plan that includes both internal and external resources creates a seamless, cost-effective process that keeps your fleet in top condition. With proper tracking and vendor management, you can optimize your maintenance strategy and reduce overall costs.

How Link-X Helped PDM Steel

PDM Steel leveraged Link-X’s fleet management system to streamline their preventative maintenance processes, significantly reducing downtime and improving operational efficiency. By utilizing Link-X’s tracking and scheduling tools, PDM Steel was able to ensure timely maintenance, extend the life of their fleet, and optimize repair costs. Total impact in excess of a $0.30 per mile reduction over the course of 2 years! Read the full case study here.

Conclusion

Preventative maintenance is an investment that pays off in reduced repair costs, extended vehicle lifespan, and improved operational efficiency. By implementing a structured maintenance plan—whether through an internal shop, preferred vendors, or a combination of both—you can keep your fleet running smoothly while maximizing cost savings.

At Link-x.com, we help fleet managers streamline maintenance tracking, optimize repair schedules, and ensure vehicles stay road-ready. Take control of your fleet’s maintenance strategy today and start reaping the benefits of a proactive approach!